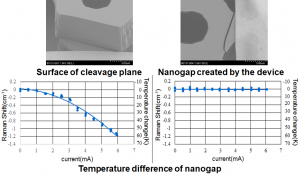

Vacuum nanogap electrodes are attracting attention because they can dramatically improve the thermal power generation efficiency which is difficult with ordinary materials, but the facing surfaces of the nanogap electrodes that can be produced by the conventional method are not parallel smooth and the area is small. Therefore, there was a problem that the power generation amount was small. In this study, we succeeded in fabricating a nanogap electrode with a large area parallel smoothed surface and a gap interval of several hundred nm by cleaving and breaking the test piece using a MEMS device. The temperature difference of the gap was measured by microscopic Raman spectroscopy.

Vacuum nanogap electrodes are attracting attention because they can dramatically improve the thermal power generation efficiency which is difficult with ordinary materials, but the facing surfaces of the nanogap electrodes that can be produced by the conventional method are not parallel smooth and the area is small. Therefore, there was a problem that the power generation amount was small. In this study, we succeeded in fabricating a nanogap electrode with a large area parallel smoothed surface and a gap interval of several hundred nm by cleaving and breaking the test piece using a MEMS device. The temperature difference of the gap was measured by microscopic Raman spectroscopy.

[Applications]

- Thermal power generation material

- Measure near-field heat transport characteristics

[Publications]